Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

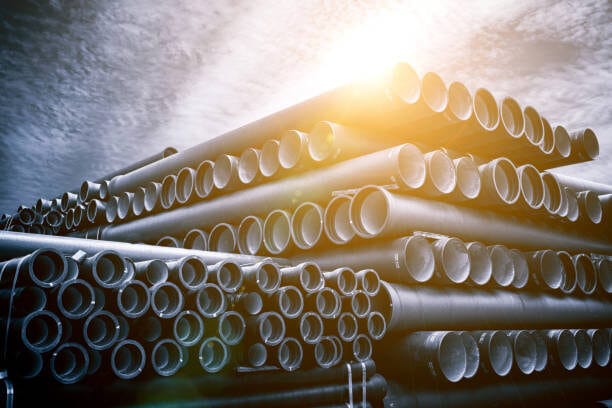

What are Metal Water Supply Pipes?

Metal water supply pipes are pipes made from steel or metal alloys used for transporting drinking water, industrial water, or irrigation water. Due to their high strength, ability to withstand high pressure, and long service life, they are widely used in municipal and rural water distribution networks, industrial systems, and various facilities.

Types of Metal Water Supply Pipes

- Galvanized Steel Pipes

- Made of steel coated with zinc

- Corrosion- and rust-resistant

- Application: potable water piping and light wastewater systems

- Black Steel Pipes (Uncoated)

- Made from plain steel without protective coating

- Commonly used in industrial and non-potable systems

- Require painting or anti-corrosion coating

- Cast Iron Pipes

- Very durable and one of the oldest types of water supply pipes

- Long lifespan but heavy in weight

- Mostly found in older municipal water networks

- Stainless Steel Pipes

- Highly resistant to corrosion, suitable for drinking water

- More expensive but extremely durable

- Carbon Steel Pipes

- High resistance to pressure and temperature

- Widely used in oil, gas, and industrial water supply systems

Sizes and Standards

- Metal water supply pipes are produced in sizes ranging from ½ inch to 120 inches.

- Wall thickness and pipe schedule are specified according to standards such as ANSI, ASTM, API, DIN.

- The larger the size and schedule, the higher the pressure resistance.

Advantages

- High mechanical strength against pressure and impact

- Can withstand high temperatures

- Long lifespan (especially with proper coating)

Disadvantages

- Susceptible to corrosion and scaling (except stainless steel or galvanized types)

- Heavy weight and more difficult to install compared to plastic pipes

- Higher cost in some alloys (e.g., stainless steel)

Applications

- Urban and rural water distribution networks

- Oil, gas, and petrochemical industries

- Firefighting systems

- Industrial and building facilities

- Agriculture and irrigation systems

Frequently Questions

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.