Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

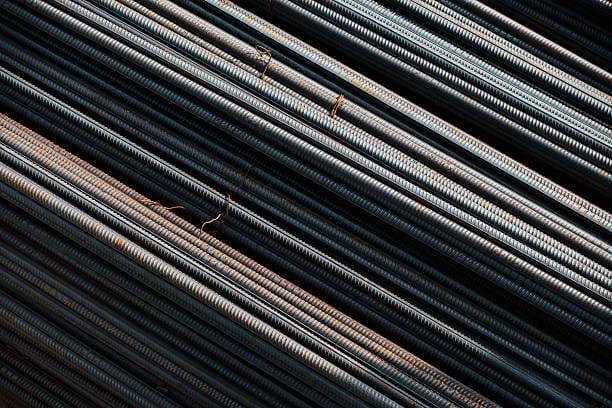

What is Rebar?

Rebar (Reinforcing Bar) is a steel rod with either a plain or ribbed (deformed) surface, used in concrete to increase tensile strength.

Concrete naturally has high compressive strength but low tensile strength, which is why rebar is embedded inside to compensate for this weakness.

Types of Rebar (by shape & production method)

- Plain Rebar (A1)

- Smooth surface without ribs.

- High flexibility and good weldability.

- Uses: stirrups, light industrial applications, reshaping on-site.

- Rarely used in primary structural elements.

- Deformed Rebar (A2, A3, A4)

- Ribbed surface for better bonding with concrete.

- Grades:

- A2 (spiral or helical ribs): semi-hard, good bendability and cutability, used for stirrups and light reinforcement.

- A3 (angled ribs): harder, more brittle, used as main longitudinal reinforcement in beams, columns, slabs.

- A4 (complex/double ribs): very strong, highly resistant, used in large-scale, earthquake-resistant structures.

- Thermo-Mechanically Treated Rebar (TMT)

- Manufactured with special technology for higher strength and reduced brittleness.

- Used in modern seismic-resistant structures.

- Stainless Rebar

- Corrosion- and rust-resistant.

- Suitable for humid areas, coastal structures, bridges.

- More expensive than standard rebar.

- Composite Rebar (FRP)

- Made of carbon, glass, or basalt fibers.

- Lightweight, corrosion-resistant.

- Used in special projects (marine structures, hospitals to avoid magnetic interference).

Rebar Sizes

Rebar is typically produced in diameters from 6 mm to 50 mm.

- 6–12 mm → stirrups, transverse reinforcement, light foundations.

- 14–25 mm → longitudinal reinforcement in beams, columns, slabs.

- 28–32 mm → heavy-duty projects like bridges, dams.

- 36–50 mm → very large-scale projects (dams, skyscrapers, industrial structures).

General Applications

- Foundation (footing) → combination of 12, 14, 16 mm rebars.

- Columns & Beams → mainly A3/A4 deformed rebars, 14–25 mm.

- Slabs & Concrete Floors → thinner rebars, 10–16 mm.

- Stirrups (ties/holders for main rebars) → plain or A2 rebars, 6–10 mm.

- Special projects (dams, bridges, metro) → thicker rebars, 25 mm and above.

Frequently Questions

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.