Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

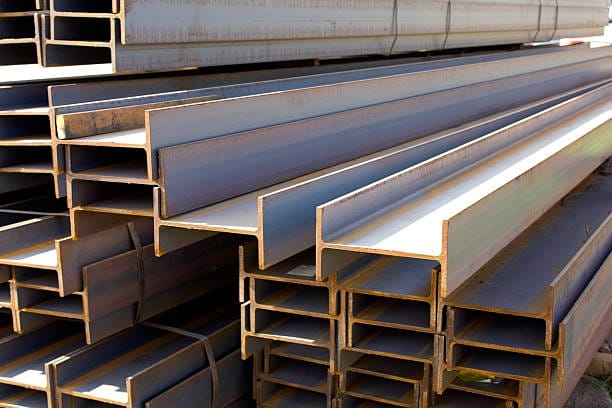

What is an I-beam?

An I-beam is one of the most important and widely used steel sections in construction and metal structures. Its main function is to withstand and transfer loads and forces applied to the structure. Thanks to their high resistance to bending and compression, I-beams are essential in steel frameworks, bridges, warehouses, and large civil projects.

Types of I-beams

IPE (European & Iranian standard)

The most common type in Iran.

Flanges (the horizontal parts) have uniform thickness.

INP (Chinese & Russian standard)

Similar to IPE, but the flange thickness decreases toward the edges.

IPB / H-beam (wide flange beam)

Flanges are wider and thicker.

Used in heavy projects like bridges, towers, and skyscrapers.

Comes in lightweight (IPBL) and heavyweight (IPBV) versions.

Castellated beam (Honeycomb beam)

Made by cutting and welding a standard I-beam.

Has hexagonal openings in the web (center part).

Useful for reducing weight and allowing installations (pipes, ducts) to pass through.

Applications of I-beams

Steel frame buildings

Main and secondary beams and columns

Bridge construction and warehouses

Industrial and civil engineering projects

Strengthening concrete structures

Standards and Sizes

I-beams are manufactured according to Stahl Table (Steel Section Table) and international standards such as DIN, ASTM, EN.

Sizes usually range from 120 mm to 600 mm in web height.

The weight per meter depends on the type and size of the beam.

Advantages

High strength and durability

Faster construction with steel frameworks

Recyclable and reusable

Disadvantages

Low resistance to fire (requires fireproof coating)

Susceptible to corrosion in humid environments (needs anti-rust protection)

Frequently Questions

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Delta Exclusive™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.